Ek bilgi icin tiklayin

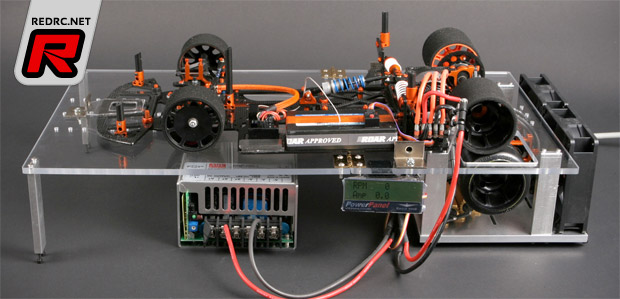

McPappy Racing have released their new brushless chassis dyno. The dyno can provide 5 styles of testing including chassis dyno testing, direct coupler in between both motors, direct coupler with flywheel in between both motors, offset motors using 2 pinions and offset motors using 2 pinions + flywheel. Chassis dyno testing offers the most convenience, as you simply set your car down on it and pull the trigger. This convenience allows you to try many variations and find the power you want quicker. You can also share numbers with other racers (regardless if the speedo and motor are different) to get the power dialed in very quickly. The chassis dyno can accommodate most 1/10th, 1/12th, and 1/18th, RC pan cars, dirt oval cars, touring cars (with front wheels propped up), buggies, etc. Direct motor only testing is a bit more work to set up, but it provides an additional level of precision because it removes some more variables. If you are looking to find small differences, direct motor only testing can be worth the effort. Whichever test method you are using, your overall goal is to turn the slave motor as fast as you can with the least amount of amps.

McPappy Racing DIY Brushless Dyno

McPappy Racing DIY Brushless DynoToday's brushless racing introduced new variables (mechanical timing, speedo timing, RPM ranges, rotor diameters) on top of the rollout variable. The new McPappy Racing DIY Brushless Dyno helps you to make sense of some of that. This dyno platform will allow you to test your motors against a brushless slave motor that provides consistent resistance from test to test.

The RC dyno can provide 5 styles of testing:

- Chassis dyno testing

- Direct coupler in between both motors

- Direct coupler with flywheel in between both motors

- Offset motors using 2 pinions

- Offset motors using 2 pinions + flywheel

Chassis Dyno Testing

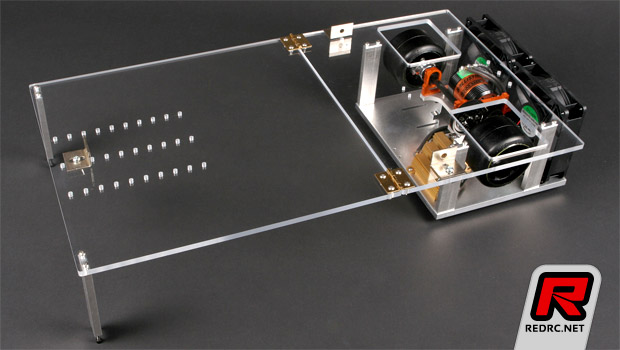

The first testing configuration is chassis dyno. Chassis dyno testing offers the most convenience, as you simply set your car down on it and pull the trigger. This convenience allows you to try many variations and find the power you want quicker. You can also share numbers with other racers (regardless if the speedo and motor are different) to get the power dialed in very quickly. The chassis dyno can accommodate most 1/10th, 1/12th, and 1/18th, RC pan cars, dirt oval cars, touring cars (with front wheels propped up), buggies, etc. The acrylic platform measures 18.1" x 10".

It can fold up for portability or to save workspace.

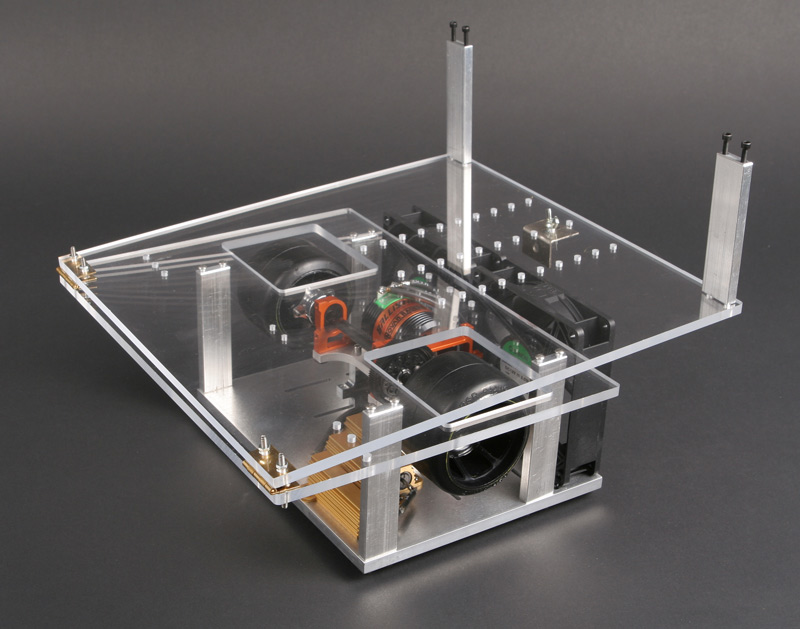

A look underneath the acrylic platform:

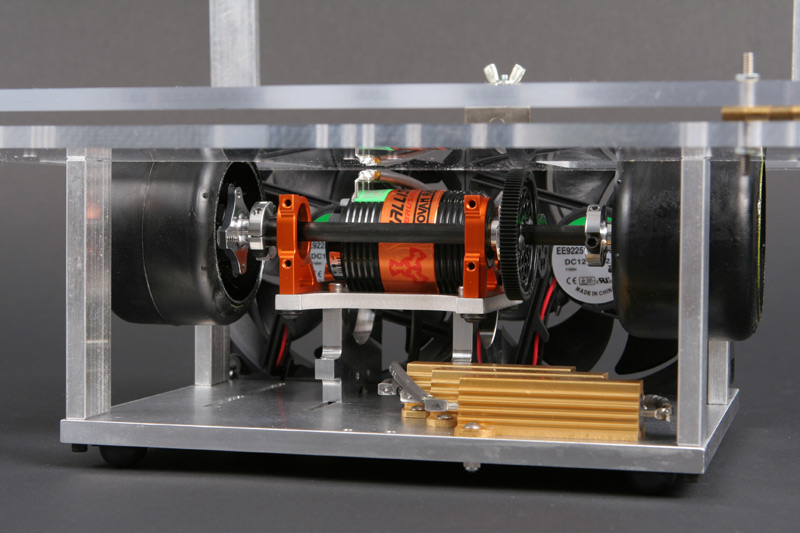

Direct 'Motor Only' Testing

Direct motor only testing is a bit more work to set up, but it provides an additional level of precision because it removes some more variables. If you are looking to find small differences, direct 'motor only testing can be worth the effort. Whichever test method you are using, your overall goal is to turn the slave motor as fast as you can with the least amount of amps.

The 2nd test configuration is a straight coupler between your test motor and the slave motor. Notice that we provide flex tubing. Compared to a solid metal coupler, in our testing, we found the flex tubing removes vibrations and produced better consistency. Click the pictures for higher resolution.

The 3rd test configuration is a direct coupler with a flywheel between both motors. This is an excellent combination of resistance to reproduce a similar track feel. The flywheel will test the bottom end of the motor under accelaration, and the brushless slave will provide resistance similar to drag produced by aerodynamics and tires at speed.

The 4th test configuration allows for the motors to be offset allowing you to use pinions. This opens up new possiblities for testing different gear ratios and assisting you with finding better rollouts. You'll be able to answer questions like, "Is higher timing + lower rollout better than lower timing + higher rollout?"

The 5th test configuration allows for a flywheel and pinions. Both types of resistance are present and you can test gear ratios as well.

(The flywheel can be positioned on the test motor or slave motor.)

Motor Mount Adjustability

The dyno base allows the motors to slide to the desired location depending on your test configuration. The slots are machined to hold the locknut so that you can tighten or loosen the screws all from the top side with a single hex driver. Soft rubber feet are included which reduces vibration.

The motor mounts can be used in the craddle method with carbon fiber brace, battery tape, and standoffs. Simply tighten down two screws to hold the motor. (The carbon fiber brace, battery tape, and standoffs can be seen in the pictures above.)

Or you can turn the mount upside down and use motor screws for an even stronger hold.

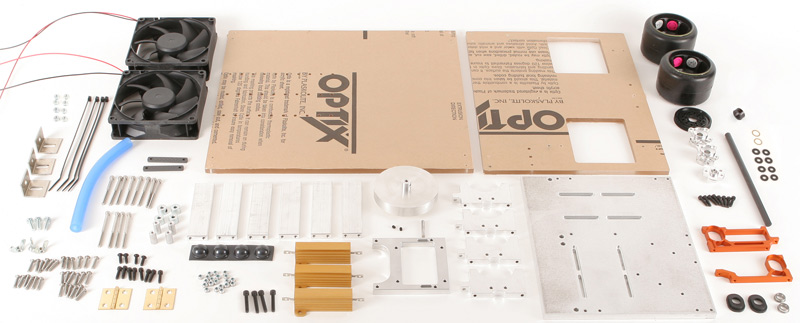

Kit Contents

The kits will be offered in 2 versions: with or without the rear axle assembly. We've designed the motor bulkhead adapter to be able to accommodate most motor bulkheads (1/10th or 1/12th). So if you have an old pan car, you can use it's bulkheads, and the rear axle assembly and choose the lower cost kit.

The items to the right side of the picture and in italics below come with the full kit with the rear axle assembly. (1)

1/4" thick 6061 aluminum dyno base (4)

6061 aluminum reversable motor mounts (1)

2.45" diameter 6061 aluminum precision flywheel with set screws (6) Chassis Dyno Support Legs (1) Chassis Dyno Bulkhead Adapter (1)

Chassis Dyno Acrylic Main Bed (1) Chassis Dyno Acrylic Bed Extension (1)

1/8" Precision ground, tight tolerance, hardened steel pinion shaft (3) Oversized Resistors (2)

92mm x 25mm Sunon Brushless 2-15V DC fans (high output 2Watts, 3000RPM, 51 CFM) (2)

Carbon fiber braces (4)

1/8" collars with set screws (1)

4" flex tubing (2) Brass Hinges (10) 4-40 Locknuts (8) 4-40 Nuts (4)

4-40 aluminum standoffs (26) 4-40 Panhead 1/2 Screws (2) 4-40 Panhead 1/4 Screws (4) 4-40 Panhead 3/8 Screws (4) 4-40 Sockethead 1 3/4 (8)

4-40 x 2 1/2" socket head screws (14) 4-40 Sockethead 1/2 (4) 4-40 Sockethead 3/4 (3) 6-32 Panhead 1/2 (3) 6-32 Wing Nuts (3) Angle Brackets (4)

Rubber sticky back feet. (4) Zip Ties (1)Left Bulkhead(1)Right Bulkhead(2)Left Hub(2)Axle Bearings(2)

BSR Cap Tires - S Pink Net Radial(2)Rear Axle Shim(1)Rear Axle Spacer(2)Rear Wheel Cap Tire(2)Ride Height Adjuster(1)Axle Shaft(1)Spur Gear Axle Adapter(1)Spur Gear 100T(8)4-40 Washer .030"

Requirements

You will need to provide a brushless slave motor (21.5 is excellent, but 17.5 will work as well) and some sort of electronics to determine RPM and Amp draw. This could be as inexpensive as an airplane tachometer and 10 gauge copper wire home-made amp draw meter, but if you want something better, we recommend the Eagle Tree eLogger V4 with the LCD panel so you don't need a computer to see the results. You don't need to buy all of their attachments, only the logger, panel and your choice of the brushless RPM sensor, magnetic RPM sensor, or optical RPM sensor. Another good option is the Novak Sentry Data Logger (Part # S2010N), although the Sentry does require a computer. It can be purchased at Novak's web store for only $69.99.

Both the Eagle Tree and Novak Sentry can export to Excel. Here are some example charts courteousy of John Stranahan. You can download the ourExcel spreadsheet here.

A power supply adds the convenience of not having to wait to charge a battery and provides the same exact power on every test. Many power supplies have voltage adjustment. Personally, I race single cell, so I bought a Mean Well 5V 120A (HRP-600-5)_power supply. This particular power supply allowed me to adjust the voltage down to 4.220V. Bonus!

Dyno Benefits

Of course, the final testing will always be the track, but when all things are equal, a dyno can offer some benefits.

- Helps you find your strongest motors.

- Find which is more efficient, mechanical timing vs. speedo timing.

- Help you find the right combination of mechanical timing, speedo timing, and RPM ranges

- Help you find which method is better: higher timing + lower rollout better than lower timing + higher rollout

- Provides an understand how different diameter rotor affect the power output.

- You can set two motors up to have identical timing so you can share rollouts between those motors.

- If you don't have an inductance meter or MMS meter, you could actually use this to determine which motor can is stronger.

- Likewise, if you don't have an rotor gauss meter you could actually use this to determine which rotor is stronger, better balanced.

- It can reveal all of the small items into it's results, like bearings, wiring, solder, rotor shimming, rotor balance, etc.

- Determine if bigger pinions (or certain brands) are more efficient than smaller pinions.

- Run the motor for a few minutes and generate a RPM chart to look at motor heat fade.

- It could potentially help you see if you have a speedo that performs better than others.

Dyno Owner's Manual (4.08MB)

Alintidir : REDRC & McPappy Racing

Bölümler

Bölümler Kategoriler

Kategoriler